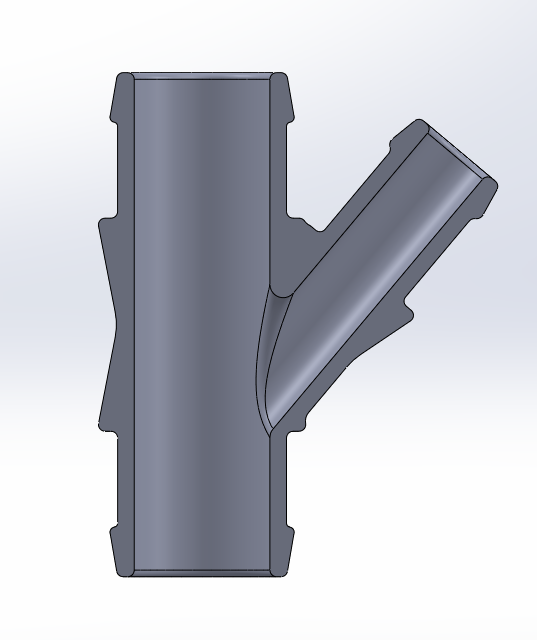

Custom 3D Printed Audi Coolant Fitting – Carbon Fiber Nylon Replacement

At NOS Manufacturing, we’re passionate about solving problems for shops and enthusiasts who need reliable parts that are no longer available on the market. Recently, we had the opportunity to help an automotive shop with a critical repair on an Audi coolant system.

The Solution: Carbon Fiber Nylon + In-House Sealing

We designed and manufactured the fitting using carbon fiber-reinforced nylon, a material known for its durability, high strength-to-weight ratio, and temperature resistance.

However, one of the realities of 3D printing is that parts can have microscopic porosity, which poses a risk for pressurized fluid systems. To address this, we applied our in-house proprietary sealing process. This post-processing method eliminates porosity, ensuring the fitting is fully leak-proof and ready for long-term use in demanding environments.

The result? A sealed, high-strength fitting capable of withstanding 200°F (93°C) at 15 PSI—meeting the requirements of an Audi coolant system with confidence.

Taking Advantage of 3D Printing Geometry

Beyond simply recreating the part, we took the opportunity to optimize the internal geometry—something not possible with injection molding.

Traditional molded parts are limited by tool access, which often results in sharp internal corners. With 3D printing, we were able to incorporate filleted transitions inside the fitting. This improvement allows:

Smoother flow paths – Coolant moves through curves instead of hitting abrupt corners.

Reduced turbulence – Sharp edges create eddies and flow separation, while fillets keep fluid dynamics consistent.

Improved cooling efficiency – Even a small increase in effective flow area and transition smoothness can enhance coolant circulation through the fitting.

This design optimization demonstrates how additive manufacturing is not just about replacing parts, but about making them better than before.

Why It Matters

This project highlights the value of modern manufacturing methods in the automotive world:

Rapid turnaround – Parts can be produced in days, not weeks.

Reliable performance – Engineered to meet the thermal and pressure demands of real-world applications.

Extended vehicle life – Obsolete components can be revived, keeping cars on the road longer.

Improved engineering – 3D printing allows for performance enhancements beyond OEM design limitations.

Bringing Old Parts Back to Life

At NOS Manufacturing, we bridge the gap between unavailable OEM parts and the performance requirements of today’s shops. From automotive to aerospace and industrial applications, our expertise in 3D printing, reverse engineering, and advanced materials processing ensures no machine is left waiting on a part that no longer exists.

If you’re a shop owner or enthusiast in need of a hard-to-find, discontinued, or custom-engineered part, reach out to us. We specialize in creating rapid, reliable, and performance-driven solutions designed to get your machines back in action.