Automotive

Automotive Engineering & Performance Solutions

NOS Manufacturing supports automotive engineering teams, performance programs, and development groups working on complex systems where performance, fitment, and manufacturability must align.

We help reduce uncertainty, validate designs early, and deliver solutions that can be built and tested with confidence.

Automotive clients typically engage us when facing:

Performance or airflow unknowns impacting outcomes

Structural or mounting concerns prior to fabrication

Fitment challenges within existing platforms

Legacy or missing reference geometry

Rapid development cycles with limited margin for rework

Automotive Challenges We Solve

Examples of automotive engagements include:

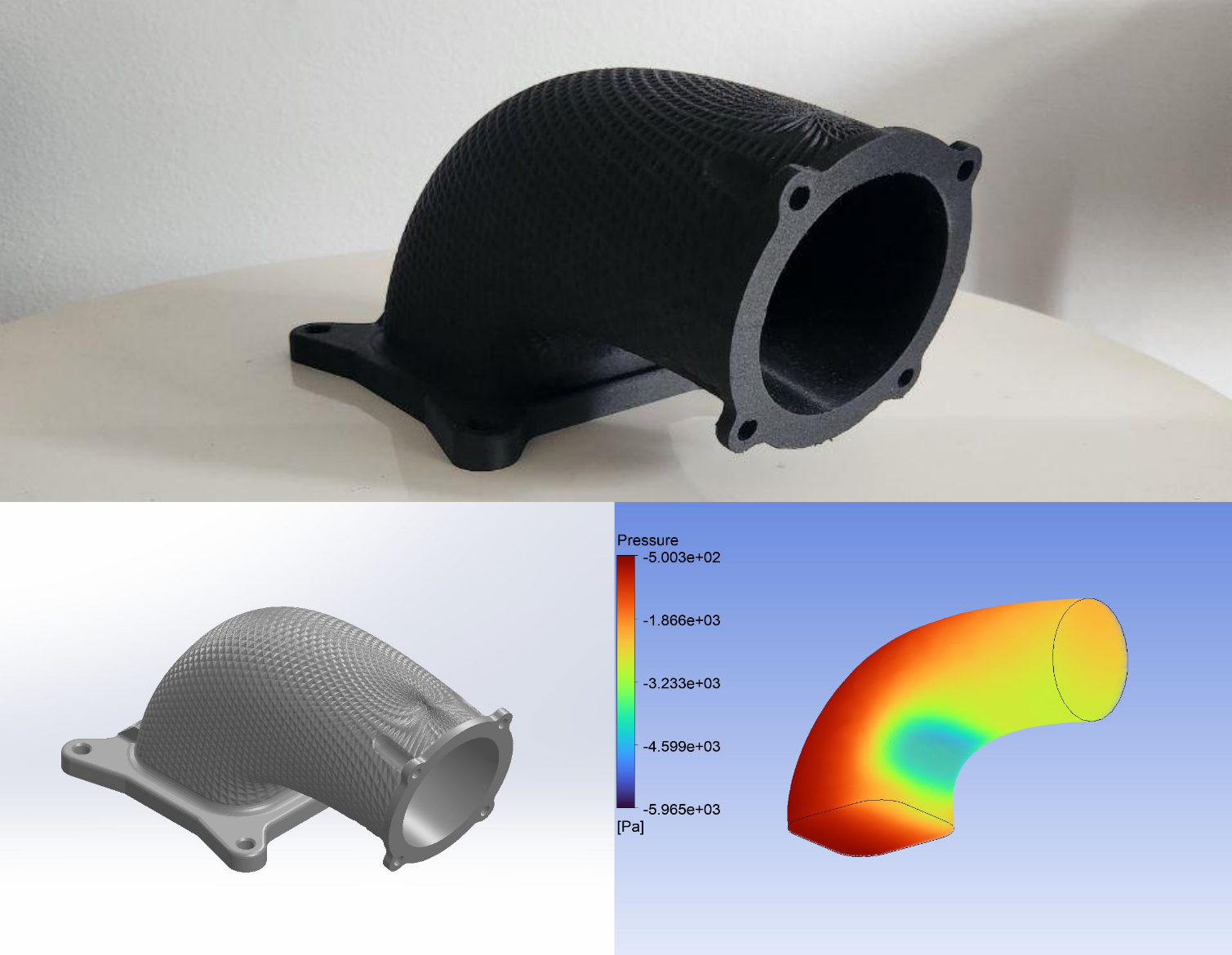

Intake or airflow system development and validation

Structural reinforcement or mounting design

Fitment verification using digital reconstruction

Prototype refinement prior to fabrication or testing

Support for custom or limited-production programs

Typical Automotive Engagements

Our automotive work commonly involves:

Engineering validation for performance and structural behavior

Reverse engineering of OEM or custom components

Intake, ducting, and airflow-related development

Composite part and tooling design

Prototyping and iteration aligned with real-world constraints

We focus on results that translate from digital models to physical builds.

How Our Solutions Apply in Automotive

Start an Automotive Conversation

If your automotive program has performance uncertainty, design constraints, or manufacturability challenges, we’re available to discuss how we can help.