New 3D Scanning Technology for Rapid Inspection, CAD Modeling & Reverse Engineering

Introducing our New 3D Scanning & Digital Metrology Setup

At NOS Manufacturing LLC we’ve long offered 3-D scanning as part of our design-engineering and reverse-engineering service stack.

Today we’re excited to announce our latest upgrade in scanning capability — the Revopoint MetroX metrology-grade 3D scanner — paired with a dedicated high-performance portable ITX workstation built in-house.

Together they enable ultra‐precise scanning, rapid turnaround, and full digital metrology for your parts, assemblies and tooling.

Why this upgrade matters

Manufacturers, machine shops, and production-assembly facilities face time and cost pressures when it comes to part digitization, inspection and reverse engineering. Traditional coordinate-measuring-machine (CMM) setups or custom inspection fixtures can be expensive, slow or logistically difficult. With our new system:

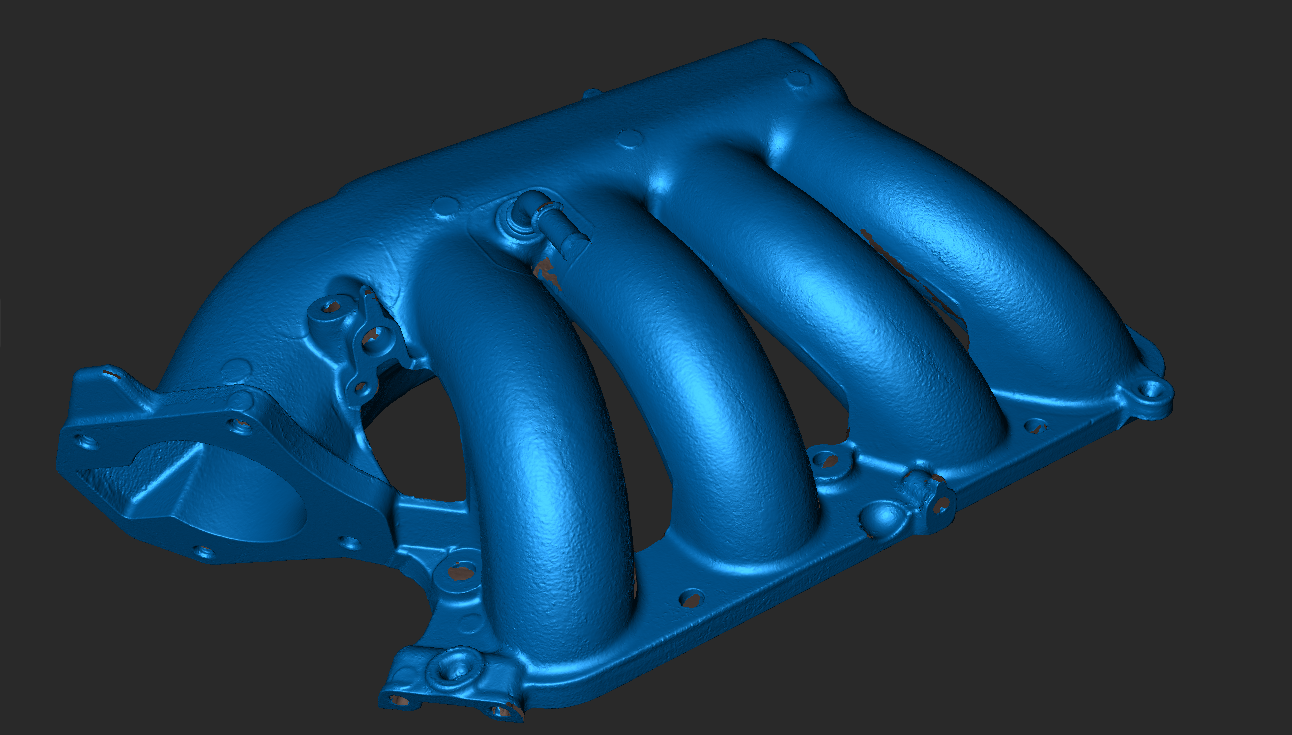

We can capture detailed geometry of complex parts (castings, sheet-metal, assemblies) with high resolution and accuracy.

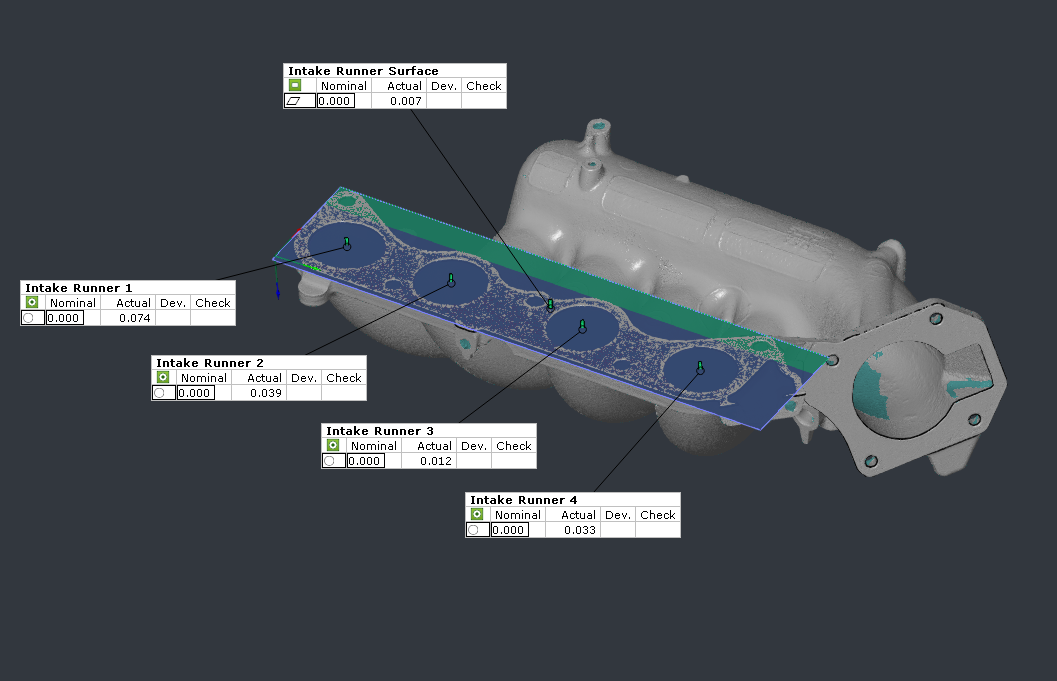

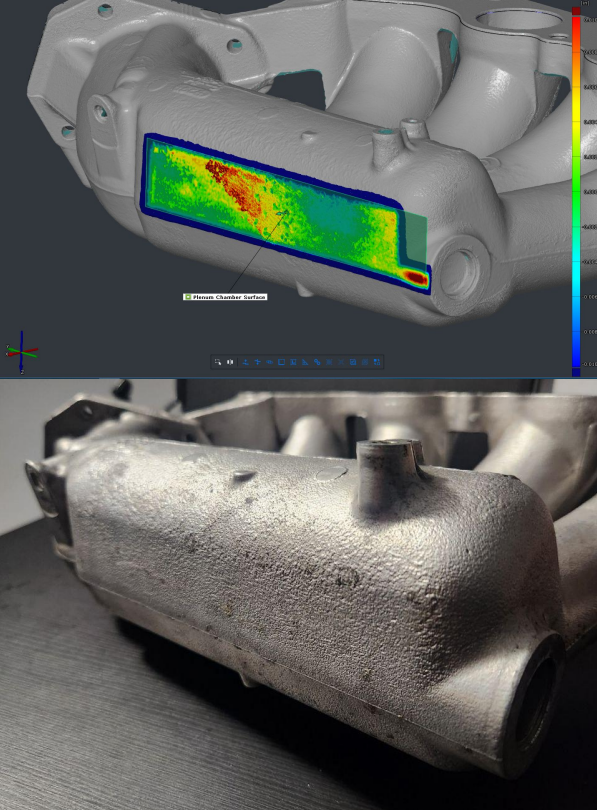

We deliver both raw point‐cloud/mesh data and full digital metrology—meaning we can extract datums, best-fit geometry (planes, cylinders, circles), heat-maps of deviation, and dimensional verification.

We can turn around scans and inspection deliverables faster, reduce your lead-time, and reduce up-front tooling or fixturing cost by leveraging the scanner + software workflow.

We can support reverse engineering: digitize the part, extract features, export for CAD, create models, integrate into assemblies, or drive additive/manufacturing workflows.

Scanner Specs

Accuracy up to 0.02 mm — tight enough for precision-machined parts, cast surfaces, and dimensional verification.

Volumetric accuracy suitable for medium-sized components — maintains stability across full manifolds, housings, brackets, and assemblies.

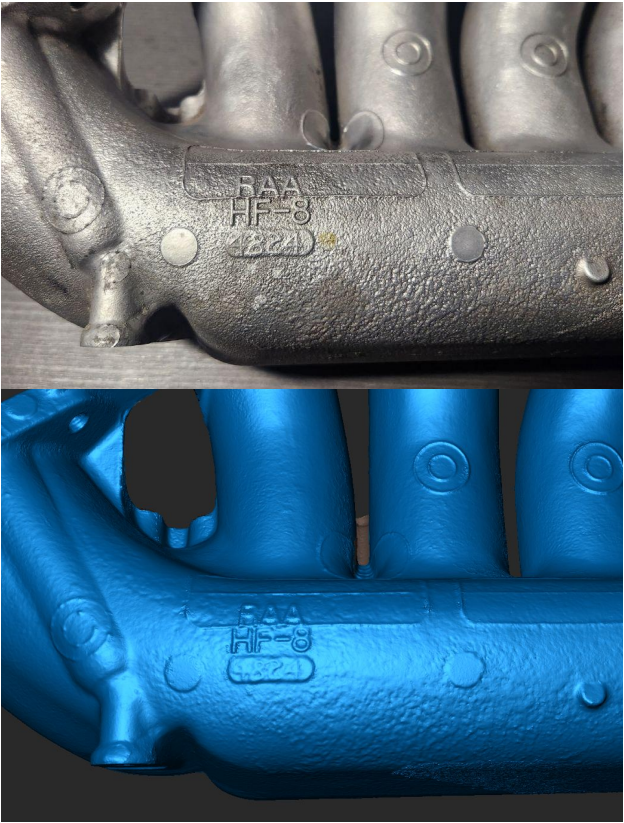

High-resolution blue-laser capture — easily picks up casting irregularities, parting lines, lettering, fillets, and edge breaks needed for manufacturing decisions.

Fast point-cloud generation — enables rapid digitization without sacrificing detail, ideal for production timelines.

Marker + feature tracking modes — stable scanning of both feature-rich castings and smooth/featureless surfaces.

Our Dedicated Scanning Workstation

To support the MetroX and ensure robust, reliable scanning (especially large/complex or high-resolution scans) we’ve built a portable compact ITX workstation dedicated solely for 3-D scanning and metrology work. Key specs:

Processor: AMD Ryzen 9 series (16 cores / 32 threads)

Graphics: NVIDIA RTX 3060 with 16 GB VRAM

14-inch touchscreen integrated in the portable ITX chassis (with carry-handle) for on-site scanning flexibility

Fully modular components for field deployment: carry-case ready, calm-environment tolerant, high-throughput scanning without crashing/usability issues

Workflow: scan → process point cloud/mesh → import into inspection software (ZEISS Inspect) → extract features & deliver to client

This build allows us to bring the lab to your part (on-site scanning), or deploy at our facility, with minimal downtime, flexible mobility, and full capability.

What This Enables for Shops & Manufacturers

Digital Metrology:

Extract planes, datums, best-fit features, and GD&T-ready geometry.

Generate flatness, circularity, and deviation heat maps directly from the scan.

Compare parts to CAD or to previous production runs.

Reverse Engineering:

Create accurate digital twins of legacy or unavailable parts.

Capture free-form surfaces and complex geometry impossible to measure with calipers or CMM alone.

Export clean data for CAD modeling, redesign, or manufacturing reference.

Production & Quality Assurance:

Reduce the need for custom fixtures or extensive CMM programming.

Speed up inspection workflows for one-off, prototype, or small-batch production.

Support pre-manufacturing fitment checks and tolerance validation.

In short, this scanner gives us accurate, repeatable, manufacturing-ready digital data, allowing us to deliver measurable results—not just pretty scans.

Why You Should Consider This Workflow

For machine shops, custom-part manufacturers, FBO/aircraft-maintenance shops and production assembly facilities, our scanning + metrology offering brings several strategic advantages:

Reduced inspection/fixture cost — Instead of designing custom fixtures and programming CMMs for one-off or low-volume parts, scanning allows flexible geometry capture and post-process analysis.

Faster turnaround — Because we can rapidly digitize and process parts we shorten the feedback loop for inspection, reverse engineering or redesign.

Better geometry capture — Traditional fixtures may only capture limited dimensions; full 3-D scanning allows you to capture free-form surfaces, casting irregularities, undercuts, internal geometry (when accessible) and fine detail.

Digital archive & reuse — Once we digitize a part, you have a digital twin you can reference, compare to future production, or use for redesign/upgrade.

Reverse engineering support — If you’re upgrading legacy parts, custom aircraft components, classic car parts, or need fitment in assemblies — our workflow captures geometry and can deliver CAD models, surface extractions, PMI (product & manufacturing information) ready for engineering.

Inspection reporting — We can provide metrology deliverables: dimensional verification, geometric tolerance checks (e.g., flatness, circularity, cylindricity, as per your spec), and heat-maps showing deviations from nominal or from prior scans.

Let’s Partner

If you’re a machine shop, production assembly facility, FBO, custom vehicle/aircraft part builder or engineering firm looking for trusted 3-D scanning, digital metrology or reverse-engineering support — please reach out. At NOS Manufacturing we offer:

On-site or in-house scanning with our portable ITX workstation + Revopoint MetroX setup

Delivery of raw scan data (meshes/point clouds) and metrology reports (measurements, best-fit geometry, deviation heat‐maps)

Reverse engineering workflows: extract datums, planes, cylinders, export CAD models (IGES/STEP), support fitment, redesign, tooling readiness

Collaborative workflow: we discuss your part, assembly or inspection spec up-front, define deliverables, and deliver in a format you can integrate into your engineering/production ecosystem

We’re confident this upgrade to our scanning capability will allow our clients to save time, reduce cost and raise the quality of their inspection and reverse-engineering pipelines.