Engineering & Manufacturing Solutions for Complex, High-Risk Programs

What We Do

NOS Manufacturing provides end-to-end engineering and manufacturing solutions for organizations where mistakes are costly and clarity matters.

We step in when designs are incomplete, data is missing, production is unstable, or internal teams need experienced engineering support without adding permanent headcount.

Our Solutions

Product & System Development

Turning early concepts, legacy designs, or incomplete systems into buildable, production-ready solutions.

Reverse Engineering & Legacy Support

Reconstructing critical parts, tooling, and assemblies when digital data is missing or outdated.

Engineering Validation & Risk Reduction

Reducing uncertainty before committing to tooling, testing, or production investment.

Manufacturing Readiness & Production Scaling

Bridging engineering and production to stabilize processes and support growth.

Quality Engineering & Digital Metrology

Identifying root causes, verifying fit, and restoring engineering intent.

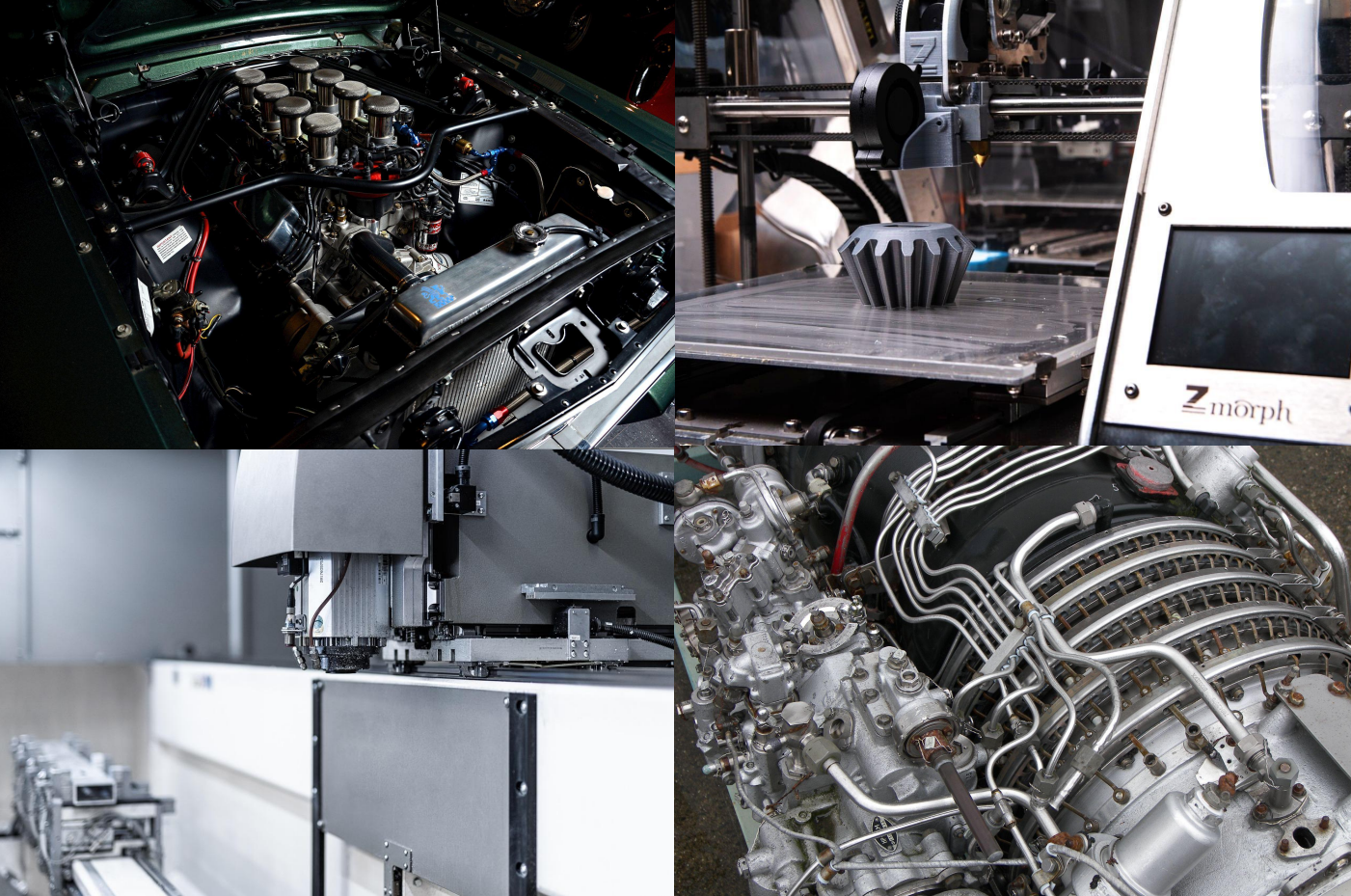

Industries We Support

Our solutions are applied across sectors where engineering decisions directly impact cost, schedule, and performance.

Manufacturing

Supporting manufacturers facing engineering bottlenecks, quality issues, and scale-up challenges.

→ View Manufacturing

Automotive

Working with automotive teams on performance, fitment, and manufacturable solutions.

→ View Automotive

Aerospace

Supporting aerospace programs with validation, legacy support, and manufacturing readiness.

→ View Aerospace

How We Work

We engage as a technical partner, not a task-based service provider.

Our approach is built around clear problem definition, early validation, manufacturable solutions, and continued support through execution.

1. Problem Definition & Scope Alignment

2. Engineering Evaluation & Validation

3. Solution Development & Manufacturing Alignment

4. Support Through Execution

Start a Technical Conversation

If your organization is facing engineering uncertainty, legacy constraints, or manufacturing challenges, we’re available to discuss whether our approach is a good fit.