Aerospace

Aerospace Engineering & Manufacturing Solutions

NOS Manufacturing supports aerospace teams facing high-risk engineering, validation, and manufacturing challenges. Our work focuses on reducing uncertainty, supporting compliance-oriented development, and delivering manufacturing-ready solutions.

We partner with engineering and operations teams where decisions carry real cost and consequence.

Aerospace clients typically engage us when facing:

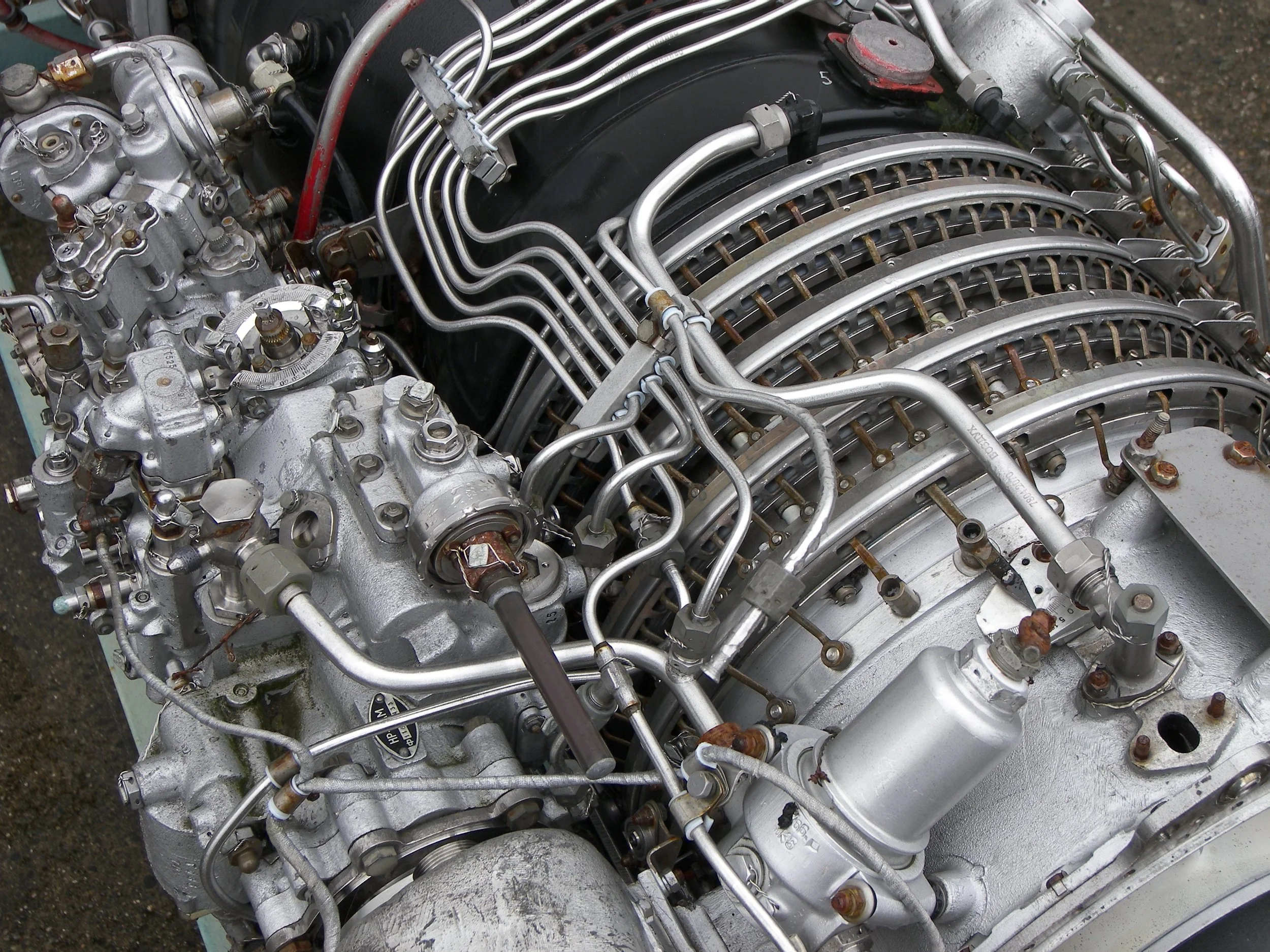

Legacy or obsolete components with missing documentation

Structural uncertainty prior to testing, qualification, or certification

Performance, airflow, or thermal issues discovered late in development

Manufacturing alignment and quality verification challenges

Aerospace Challenges We Solve

Examples of aerospace support include:

Reconstructing legacy components to support continued operation

Validating designs prior to physical testing

Supporting prototype and pre-production hardware development

Identifying and resolving fitment or quality issues

Providing overflow engineering capacity for constrained teams

Typical Aerospace Engagements

Start an Aerospace Conversation

If your aerospace program is facing technical uncertainty, legacy constraints, or manufacturing risk, we’re available to discuss how we can help move it forward.

Contact us to start an engineering-driven aerospace conversation.

Our aerospace work commonly includes:

Engineering validation to reduce structural and performance risk

Reverse engineering and digital reconstruction of legacy parts

Prototyping and tooling support for qualification efforts

Manufacturing readiness and quality alignment

Digital metrology for verification and fitment validation

All work is performed with an emphasis on accuracy, traceability, and practicality.