ASTM C39 and C109 Concrete Molds

Custom ASTM Concrete Molds — Affordable, Reusable, and Built for Flexibility

Recently, I had a client reach out with a problem that’s more common than people think—they needed to cast a few concrete samples for lab testing (ASTM C39 cylinders and ASTM C109 cubes), but weren’t looking to spend hundreds of dollars on permanent, commercial-grade molds they’d likely only use once.

This got me thinking: why not apply the power of rapid prototyping to this situation?

I designed and 3D printed custom molds specifically for ASTM C39 (4x8" cylinder) and ASTM C109 (2x2" cube) tests. The molds were made from PETG, a material that’s both durable and highly resistant to sticking—perfect for concrete, epoxies, and resins. This meant samples could be easily demolded without needing aggressive release agents, and the molds themselves could be cleaned and reused.

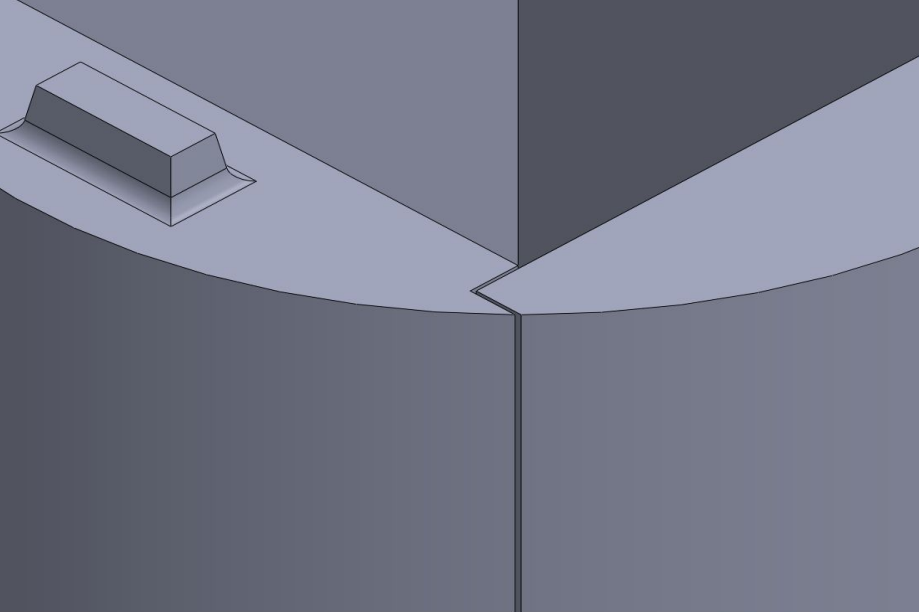

One of the more thoughtful design elements was using a two-piece split mold with V-groove alignment seams. This design achieved three things:

Maximized surface contact between mold halves for better stability

A liquid-tight seal when paired with a bead of silicone—easy to apply and even easier to peel off post-cure

Simplified assembly and disassembly for the user, especially those unfamiliar with lab mold handling

What people often overlook is how empowering it is to have full control over geometry. While these shapes were simple and test-specific, the ability to 3D print custom molds in any size, shape, or standard opens the door to endless applications—from custom R&D forms to architectural or stress-specific designs.

The final result?

✔ Reusable molds

✔ A fraction of the cost of commercial options

✔ Accurate, lab-ready samples that met ASTM test requirements

If you’ve ever thought about casting your own cement, concrete, or epoxy forms—whether for structural testing or creative prototyping—3D printing opens a whole new world of flexibility and affordability.