Industries

Industries We Support

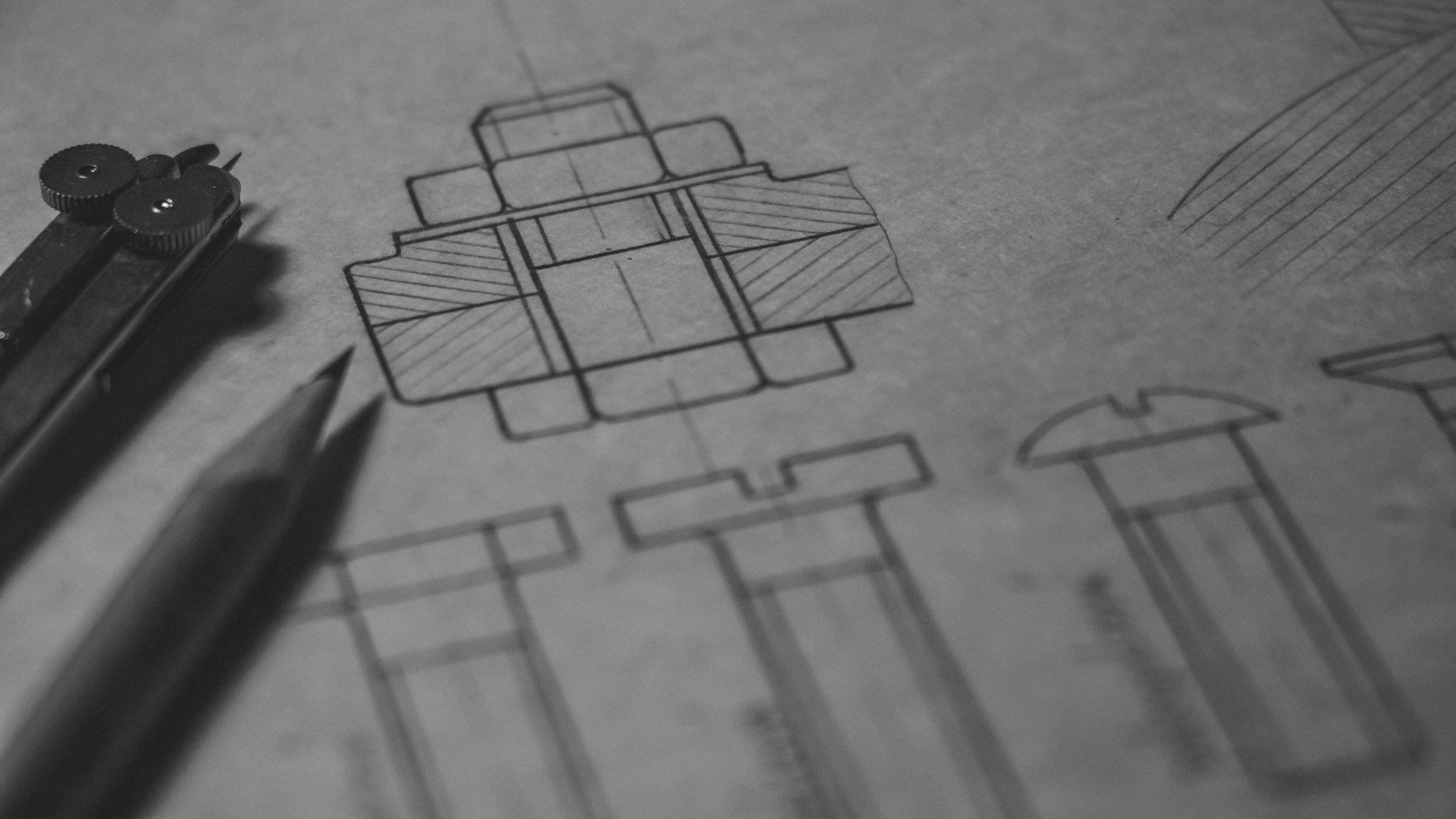

While our engineering and manufacturing solutions apply across many sectors, our work is most commonly applied in manufacturing, automotive, and aerospace programs where engineering decisions directly impact cost, schedule, performance, and long-term reliability.

Each industry presents unique constraints, but the underlying challenges are consistent: uncertainty, legacy limitations, manufacturing risk, and the need for buildable solutions. We partner with teams to resolve these challenges with clarity and accountability.

Manufacturing

Manufacturing organizations often face production bottlenecks, legacy constraints, quality issues, or limited internal engineering capacity. We work alongside manufacturers to stabilize processes, resolve technical gaps, and support scalable growth.

Common challenges we address:

Legacy parts or tooling with missing or outdated data

Production quality issues or tolerance drift

Transition from prototype to repeatable production

Limited internal engineering or technical bandwidth

- Learn more

Automotive

Automotive programs demand performance, speed, and manufacturability—often under tight timelines. We support engineering and development teams working on performance systems, custom components, and production-intent designs.

Common challenges we address:

Performance or airflow uncertainty

Structural or mounting concerns prior to fabrication

Fitment issues within existing platforms

Rapid iteration without excessive rework

- Learn More

Aerospace

Aerospace programs operate under high technical and quality standards where mistakes are costly. We support teams facing validation challenges, legacy part constraints, and manufacturing readiness concerns.

Common challenges we address:

Obsolete or undocumented components

Structural uncertainty prior to testing or qualification

Performance or thermal concerns identified late in development

Manufacturing and quality alignment issues

- Learn More