Solutions

Engineering & Manufacturing Solutions for Complex, High-Risk Programs

NOS Manufacturing provides end-to-end engineering and manufacturing solutions for organizations facing technical uncertainty, production bottlenecks, legacy constraints, or scale-up challenges.

We are not a task-based service provider.

We partner with teams to take ownership of problems, reduce risk, and deliver solutions that are technically sound, manufacturable, and aligned with real-world constraints.

Our solutions are designed for programs where mistakes are costly and decisions matter.

Our Solution Areas

Product & System Development

From early concept to production-ready systems

Many teams have ideas, legacy products, or partially developed designs that are not yet manufacturable, scalable, or technically validated. We step in to take ownership of the engineering process and guide products through the full development lifecycle.

This solution supports:

Early-stage concepts, napkin sketches, or incomplete designs

Redesigns of existing or underperforming products

Complex mechanical systems and assemblies

Design for manufacturability across machining, molding, casting, and fabrication

Outcome:

Clear, buildable designs with defined engineering intent, reduced rework, and a realistic path to production.

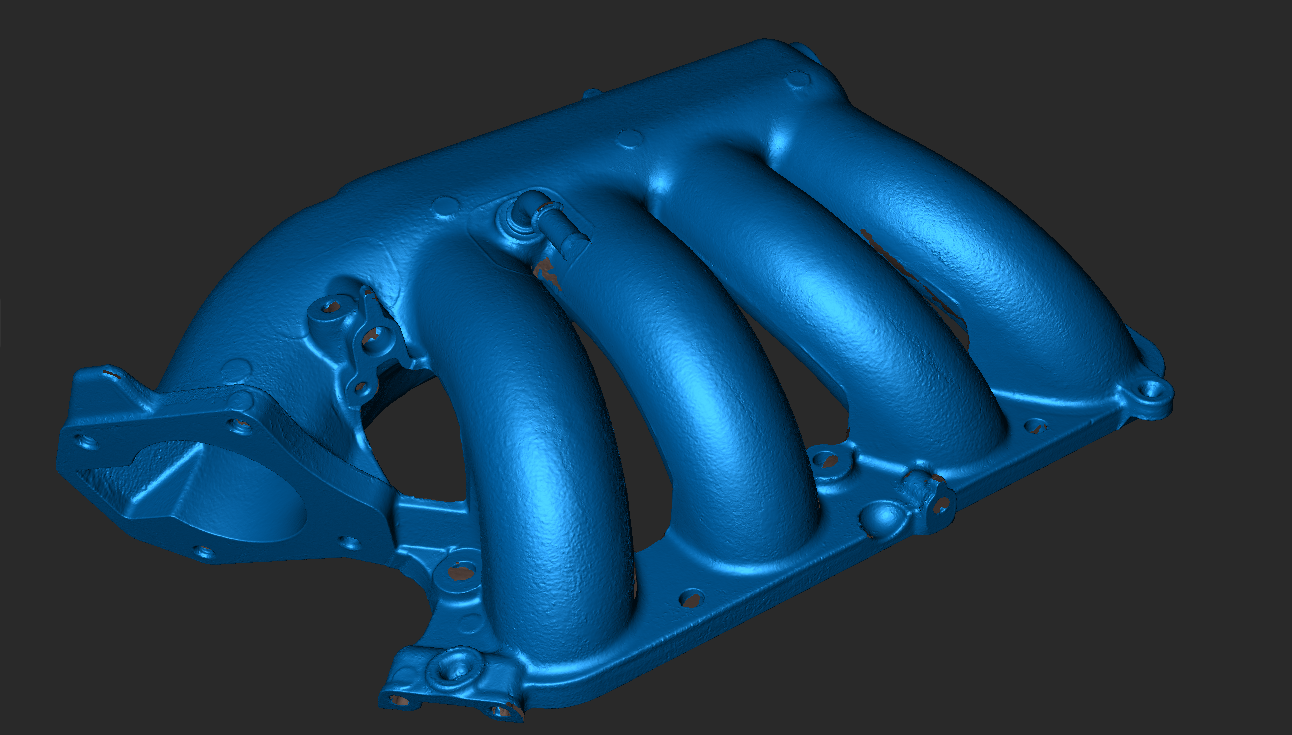

Reverse Engineering & Legacy Support

Reconstructing critical parts, systems, and tooling when data is missing

When physical parts exist but digital data does not, production, maintenance, and redesign efforts stall. We provide accurate digital reconstruction of existing components to restore continuity and enable informed engineering decisions.

This solution supports:

Obsolete or unsupported components

Legacy parts with missing or outdated drawings

Competitor or benchmark product analysis

Fitment validation within existing assemblies

Outcome:

Accurate digital models that enable redesign, validation, manufacturing, and long-term support.

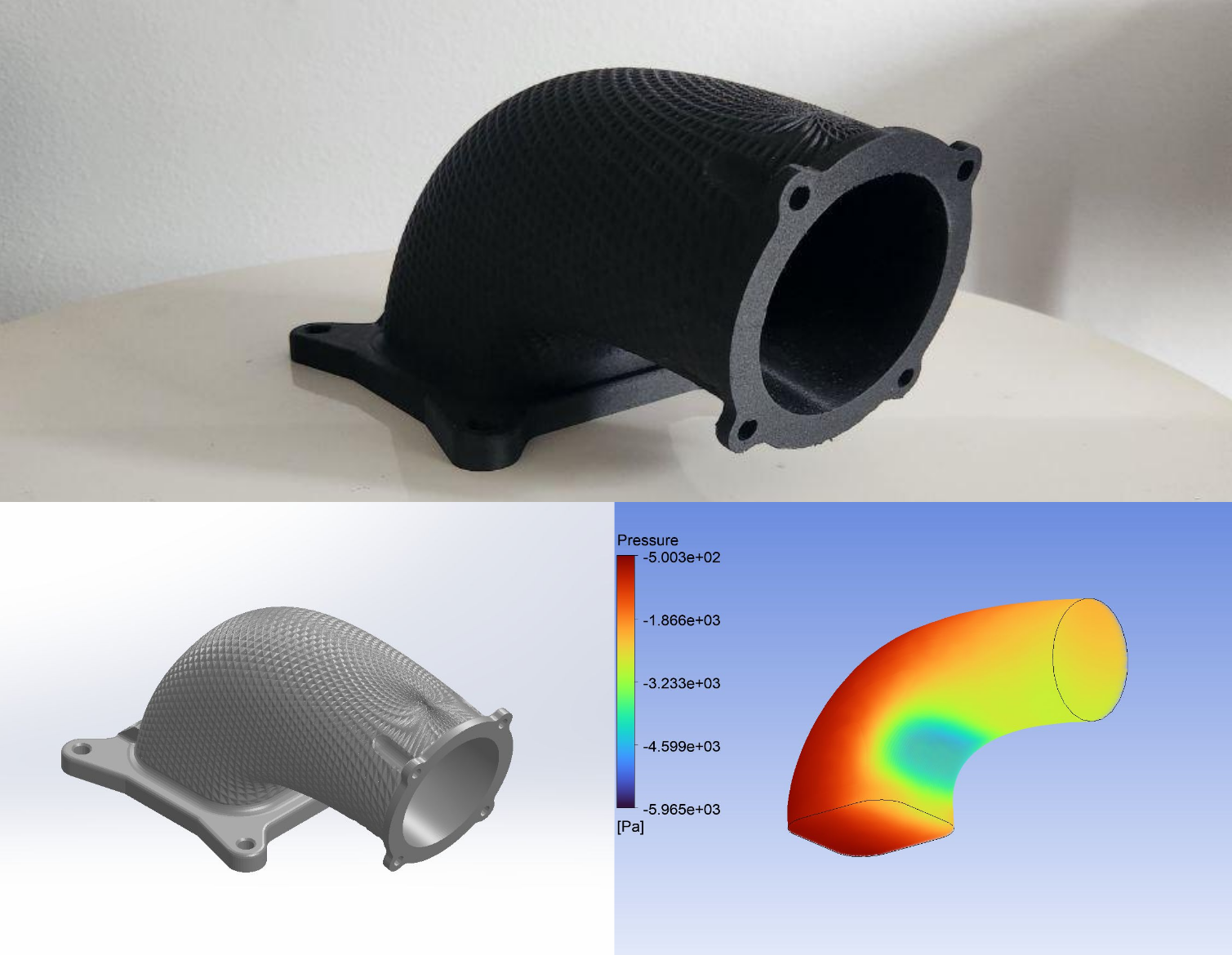

Engineering Validation & Risk Reduction

Reducing uncertainty before tooling, testing, or production investment

Engineering decisions made without validation often lead to costly redesigns and delays. We help teams evaluate performance, structural behavior, and operating conditions early—when changes are least expensive.

This solution supports:

Structural performance and load evaluation

Airflow, pressure drop, and thermal behavior analysis

Impact, vibration, and dynamic event evaluation

Lightweighting and geometry optimization

Outcome:

Engineering confidence before committing to tooling, testing, or production spend.

Manufacturing Readiness & Production Scaling

Turning designs into repeatable, buildable reality

A design that works on paper can still fail in production. We bridge the gap between engineering and manufacturing to ensure designs translate cleanly into physical parts and scalable workflows.

This solution supports:

Prototype development and iteration

Composite tooling, molds, and casting patterns

Transition from prototype to low- or mid-volume production

Vendor sourcing, coordination, and quality oversight

Production workflow and quality system setup

Outcome:

Stable manufacturing processes, reduced bottlenecks, and smoother scale-up to production.

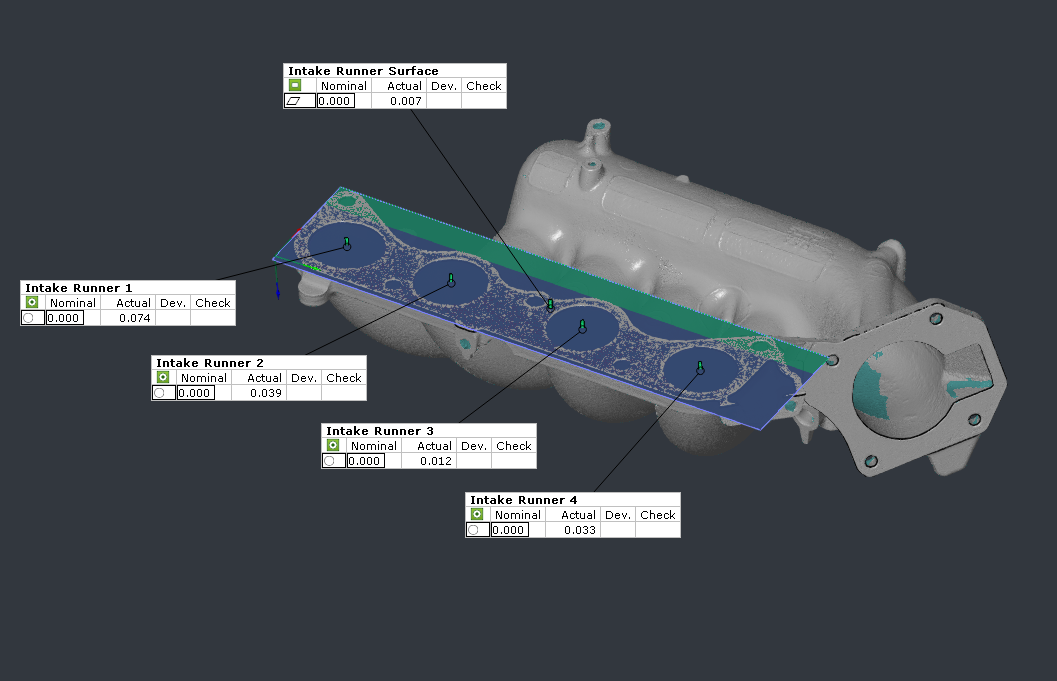

Quality Engineering & Digital Metrology

Identifying problems, verifying fit, and restoring engineering intent

When parts don’t fit, assemblies drift, or quality issues emerge, rapid and accurate diagnosis is critical. We use digital metrology and engineering analysis to identify root causes and restore control.

This solution supports:

Dimensional verification and deviation analysis

Fitment validation for assemblies and interfaces

Supplier quality investigation and comparison

Root-cause analysis of manufacturing issues

Outcome:

Clear identification of quality issues, faster corrective action, and improved consistency.

Who These Solutions Are For

Our solutions are best suited for organizations that:

Face complex or high-risk engineering challenges

Need external expertise without adding full-time staff

Require both engineering judgment and manufacturing practicality

Value long-term reliability over short-term fixes

We are not positioned as a commodity service provider.

We are a technical partner for teams that need clarity, ownership, and results.

How Our Solutions Are Delivered

Our solutions are applied across industries including aerospace, automotive, manufacturing, and industrial equipment. While the applications vary, the approach is consistent:

Define the problem clearly

Validate assumptions early

Design with manufacturing reality in mind

Deliver solutions that can be built, scaled, and supported

We work closely with engineering, operations, and leadership teams to ensure alignment from concept through execution.

Start a Technical Conversation

If your organization is facing engineering uncertainty, legacy constraints, or manufacturing challenges, we’re available to discuss how our solutions can help move your program forward.

Contact us to start a focused, engineering-driven conversation.