Engineering Design and Analysis

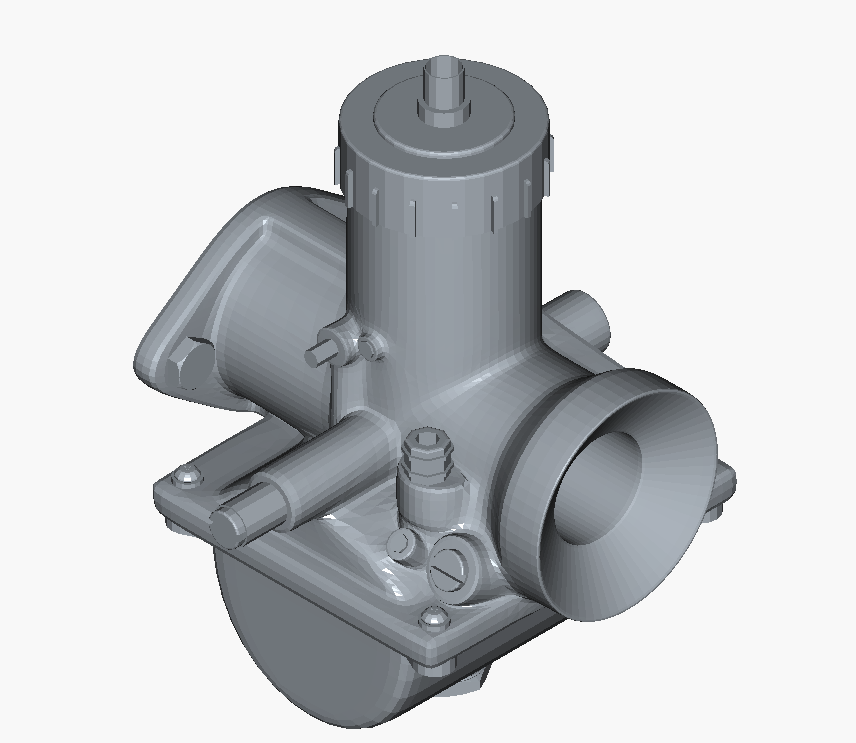

Advanced 3D CAD Design & Modeling - Creation of precise parts and assemblies using industry-leading CAD tools, optimized for real-world manufacturability and performance.

Design for Manufacturability (DFM) - Parts are engineered with the intended manufacturing process in mind—reducing cost, simplifying production, and improving yield without compromising function.

Engineering Drawing & Documentation - Development of complete drawing packages, including geometric dimensioning and tolerancing (GD&T), exploded views, part lists, and supplier-ready BOMs.

Prototype Development & Fit/Function Testing - Rapid prototyping using 3D printing and other methods to test component fit, assembly interaction, and real-world usability.

Simulation & Performance Analysis - Unified simulation support across:

Static Analysis for stress, strain, and deformation

Dynamic Motion & Vibration Simulation for moving assemblies and fatigue

Computational Flow Analysis (CFD) for internal flow paths and aerodynamic optimization

These simulations validate design integrity and ensure functionality before production.