Services

-

Our AI-driven solutions provide real-time insights and smart recommendations to improve efficiency and reduce Administrative workload

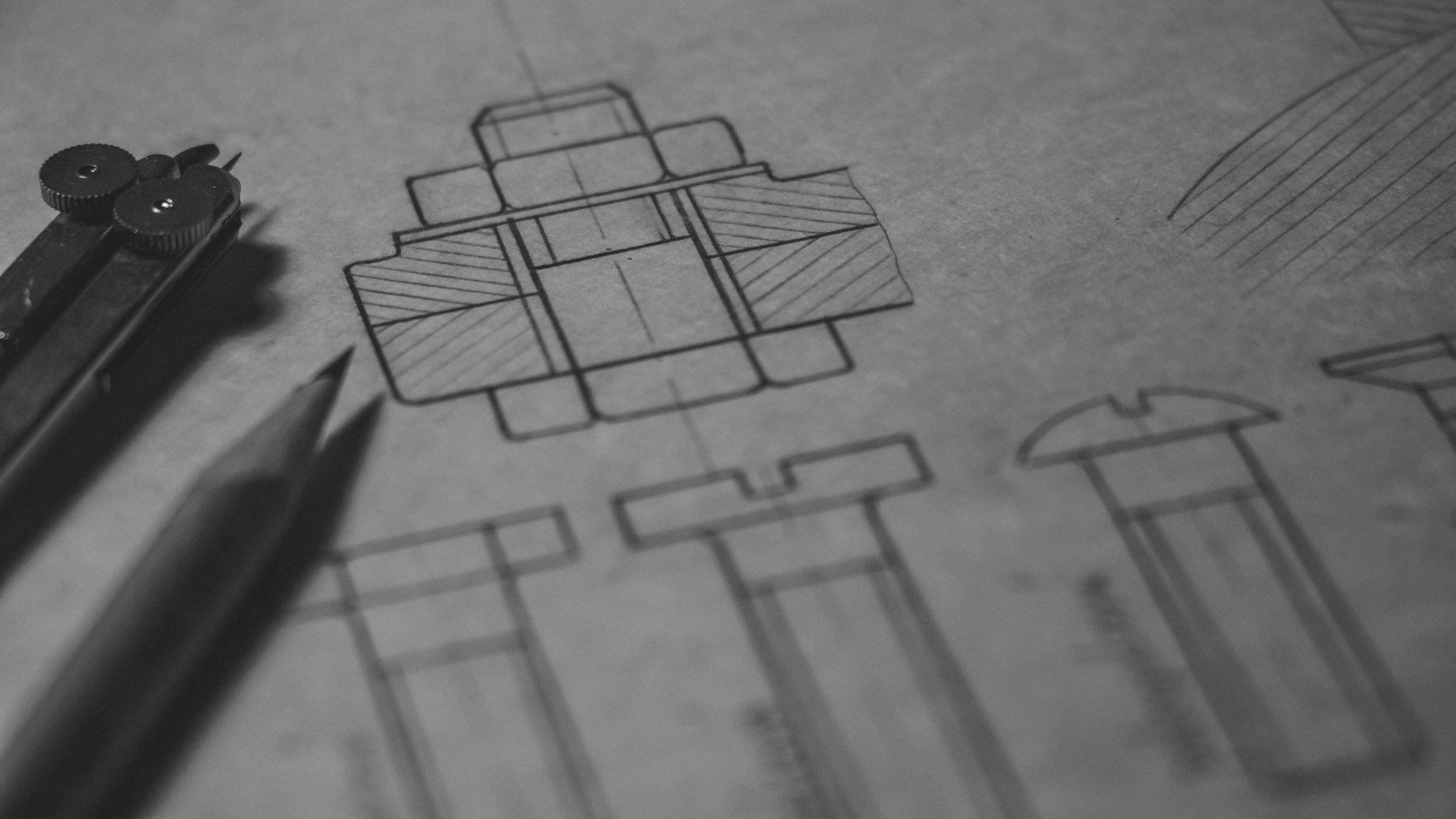

Automated Blueprint Analysis - AI models trained to read and interpret engineering drawings for part features, tolerances, and material callouts.

Specification & Standards Parsing - Extracts key requirements from industry standards (e.g., ASME, ISO, MIL-SPEC) and customer-specific documentation for compliance tracking.

Document Intelligence & Reusability - Learns from large technical documents (e.g., work instructions, quality plans, technical data packages) and makes relevant information reusable for future projects and workflows.

Smart Administrative Automation - Generates reports, fills templates, flags missing data, and assists with contract reviews, RFQs, and internal checklists—all from pre-trained document intelligence.

Process Compliance & Standardization - Helps ensure shop floor documentation, engineering processes, and manufacturing operations align with required specs and standards.

-

Ensure your business meets the highest industry standards with our certification support services. We help you achieve and maintain compliance with AS9100D, ISO9001, and ISO/TS 16949, ensuring quality, consistency, and customer satisfaction.

Compliance Assurance – Meet industry and regulatory requirements

Process Improvement – Enhance efficiency and consistency across operations.

Audit Preparation – Get expert guidance for internal and external audits.

Risk Management – Identify and mitigate potential quality risks.

Global Recognition – Strengthen your credibility in the marketplace.

-

Advanced 3D CAD Design & Modeling - Creation of precise parts and assemblies using industry-leading CAD tools, optimized for real-world manufacturability and performance.

Design for Manufacturability (DFM) - Parts are engineered with the intended manufacturing process in mind—reducing cost, simplifying production, and improving yield without compromising function.

Engineering Drawing & Documentation - Development of complete drawing packages, including geometric dimensioning and tolerancing (GD&T), exploded views, part lists, and supplier-ready BOMs.

Prototype Development & Fit/Function Testing - Rapid prototyping using 3D printing and other methods to test component fit, assembly interaction, and real-world usability.

Simulation & Performance Analysis - Unified simulation support across:

Static Analysis for stress, strain, and deformation

Dynamic Motion & Vibration Simulation for moving assemblies and fatigue

Computational Flow Analysis (CFD) for internal flow paths and aerodynamic optimization

These simulations validate design integrity and ensure functionality before production.

-

Process Optimization & Six Sigma Implementation - Identify inefficiencies and eliminate waste using data-driven Six Sigma methodologies. From root cause analysis to statistical process control, we apply DMAIC and lean principles to enhance throughput, reduce cycle time, and improve first-pass yield.

Industrial Engineering & Workflow Efficiency - Design and optimize manufacturing layouts, work cells, and production systems to balance labor, minimize bottlenecks, and reduce handling time. We evaluate takt time, line balancing, and material flow to align operations with production targets.

Equipment Selection & Capital Planning - Assist in selecting the right equipment for manufacturing operations—based on volume, precision, and process capability. We provide recommendations on machines, tools, automation systems, and layout integration to match performance, scalability, and ROI expectations.

-

High-Strength Polymer & Composite-Based Printing - Production of durable parts using engineering-grade thermoplastics (e.g., Nylon, Polycarbonate) and fiber-reinforced composites for high-load, high-heat, and chemically resistant applications.

Complex Geometry Fabrication - Leverage additive manufacturing to produce parts with intricate internal features, lattice structures, undercuts, and organic curves that are not possible or cost-effective with traditional methods.

End-Use Parts & Tooling Applications - Manufacture low-volume production parts, jigs, fixtures, and custom tooling components that meet real-world operational demands—whether for aerospace, industrial, or custom commercial applications.

Design Flexibility & Iteration Support - Quickly revise or customize production parts on a per-batch basis without retooling, enabling iterative refinement and design responsiveness.

Book a Free Consultation

Let us Get to know you and your Company