Aerospace & Aviation Systems

Reverse-engineered components and support equipment for general aviation, MRO, and FBO operations.

-

When replacement parts are no longer available, existing components are scanned, digitally reconstructed, and optimized for function and manufacturability. Replacements can be prototyped in composite or plastic, or prepared for CNC/fiberglass production.

-

Lightweight, durable replacements for damaged or corroded panels and Parts, built using a carbon-nylon core with fiberglass layup, validated through structural simulation and tailored to fit the aircraft's geometry.

-

Precision 3D scanning captures complex surfaces and assemblies, enabling exact digital replication for repairs, retrofits, or design modifications. Ideal for interior fittings, panels, and custom avionics enclosures.

-

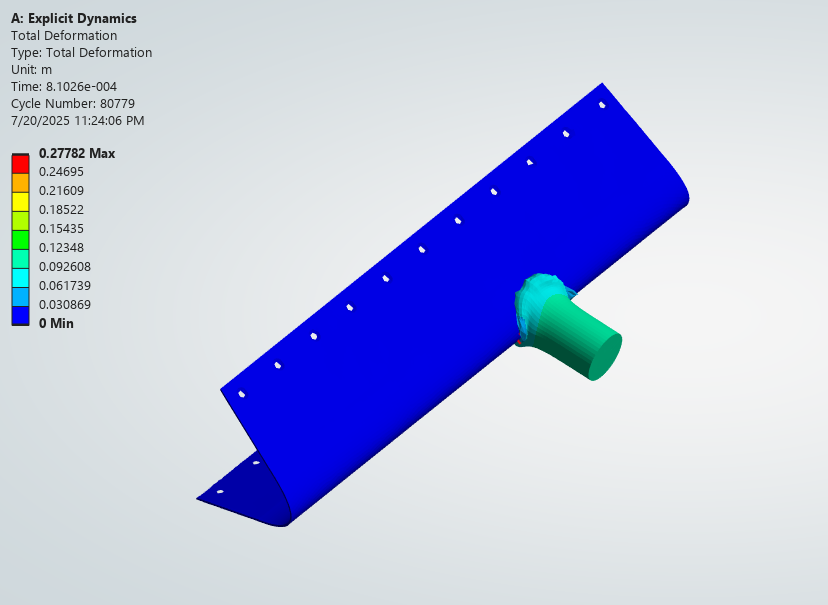

Finite element simulations (static, vibration, thermal, pressure) validate structural and aerodynamic performance. Results ensure parts meet the strength and behavior expected under real operating loads.

-

Design and fabrication of aircraft-specific jigs, positioning tools, and maintenance aids to streamline ground servicing and ensure consistent installation or repair workflows.